Computer Vision for Quality Assessment of Printed Silver Conductors

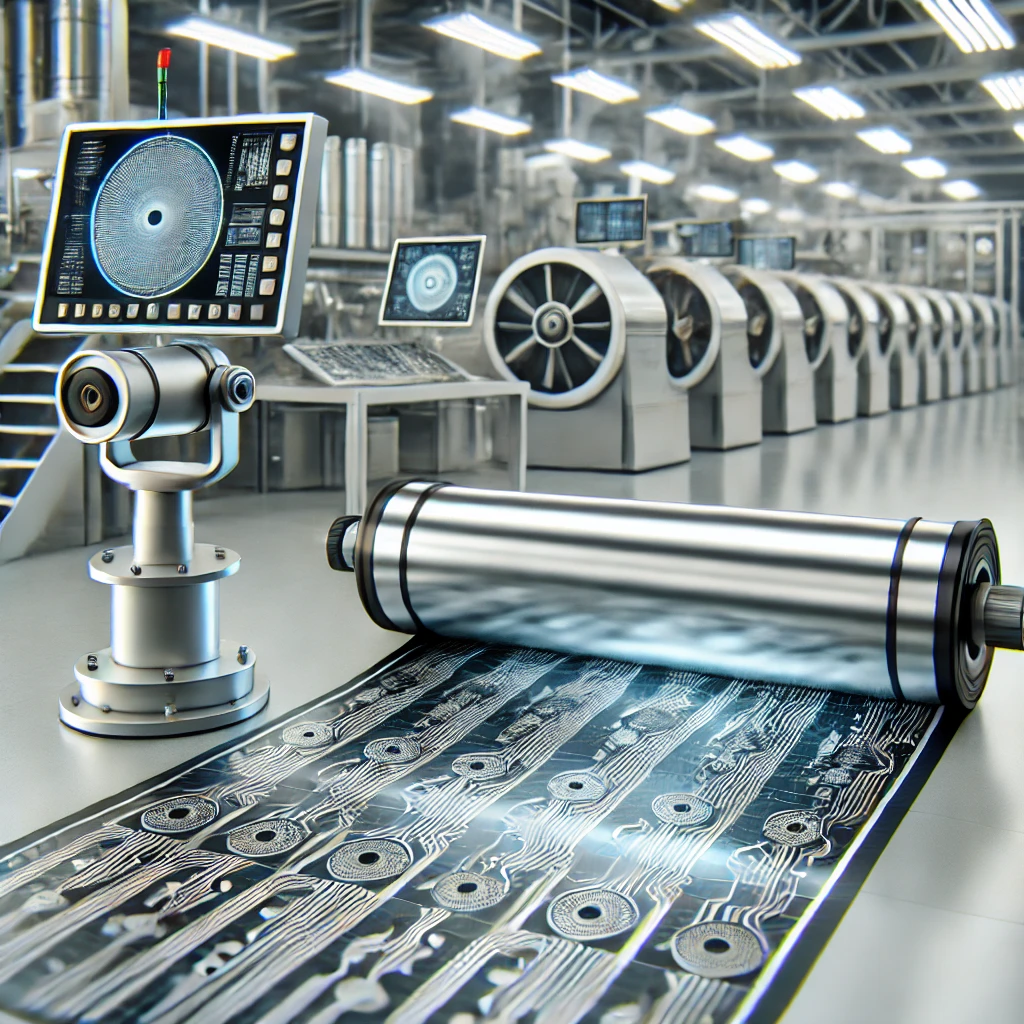

This research paper, authored by Dr. Amin Amini and colleagues, presents a novel computer vision-based technique for assessing the quality of roll-to-roll (R2R) printed silver conductors on flexible plastic substrates. The rapid development of flexible electronics, such as wearable devices and smart packaging, has highlighted the importance of precise quality control in manufacturing processes. Traditional inspection methods are often time-consuming, expensive, and less efficient when dealing with high-speed R2R production lines.

The proposed technique utilises computer vision algorithms to analyse the printed silver conductors in real-time, detecting defects such as inconsistencies in thickness, cracks, and surface irregularities. By leveraging advanced image processing and machine learning methods, this approach ensures faster and more accurate quality assessment compared to conventional techniques.

Through experimental validation, the researchers demonstrated that their system not only reduces inspection time but also improves defect detection accuracy. This breakthrough offers a significant advantage for manufacturers aiming to enhance the reliability and cost-efficiency of flexible electronic components.

This work underscores the power of combining computer vision and machine learning to solve real-world challenges in manufacturing. It also sets the stage for further innovations in quality control systems for emerging technologies.

Read the full paper here: A Computer Vision-Based Quality Assessment Technique for R2R Printed Silver Conductors on Flexible Plastic Substrates